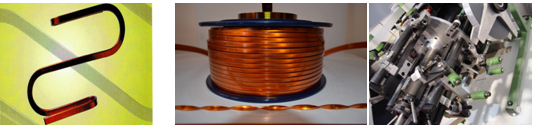

Polyimide Covered Copper Wire

Kapton® in Polyimide covered round & rectangular / flat copper wire is the condensation product of an aromatic tetra basic acid and an aromatic diamine. It has no melting point, is infusible and self-extinguishing (does not support combustion). Kapton® (Brand Name of DuPont’s Polyimide Film) Covered Wires offers a wide range of applications in the construction of motors (specially in traction motors), aerospace equipments. It provides insulation with high electrical, thermal and mechanical properties over a temperature range of -196°C to +250°C. It provides higher Break Down Voltage (more than 8 KV BDV) as well as Temperature Class (220 °C) as compare with other insulated conductors. Insulating materials in traction motors have to withstand high temperatures and frequent changes of load and temperature. Standard materials applied for conductor insulation in Traction Motor application is polyimide film. It has excellent chemical resistance; there are no known organic solvents for the film. polyimide does not melt or burn as it has the highest flammability rating. The outstanding properties of polyimide permit it to be used at both high and low temperature extremes where other organic polymeric materials would not be functional. polyimide gives conductors space saving, which ultimately yields more power without increasing motor size. Polyimide provides exceptional overload protection and long motor life, even in the most demanding applications and environments.

Features

- Conductors

Copper and Aluminum (Round and flat wire)

- Standard

IEC - EN 60317-43 EN 60317-44

- Voltage and Insulation Thicknesses

5 KV (1 layer %50 over 0,15Micron)

10 KV (2 layer %50 over 0,30 Micron)

15KV (3 layer %50 over 0,40Micron)

20KV (4 layer %50 over 0,50 Micron)

- Production Range

Thickness: 1 - 8 mm

Width: 3 - 20 mm

Diameter: 3 - 10 mm

- Conductors Copper and Aluminum (Round and flat wire)

- Standard IEC - EN 60317-43 EN 60317-44

- Voltage and Insulation Thicknesses 5 KV (1 layer %50 over 0,15Micron)

- Production Range Thickness: 1 - 8 mm

10 KV (2 layer %50 over 0,30 Micron)

15KV (3 layer %50 over 0,40Micron)

20KV (4 layer %50 over 0,50 Micron)

Width: 3 - 20 mm

Diameter: 3 - 10 mm